Running a manufacturing company means constantly juggling production schedules, managing inventory, and keeping a keen eye on your finances. It’s a dynamic environment where every decision, from purchasing raw materials to hiring new staff, has a direct impact on your bottom line. Without a clear financial roadmap, it’s easy to lose track of where your money is going and where it needs to be invested for growth.

This is precisely where a robust budget comes into play. It’s not just about tracking expenses; it’s about strategic planning, forecasting future needs, and setting realistic goals for your operations. A well-designed budget helps you anticipate challenges, identify opportunities for efficiency, and ultimately, ensure the long-term sustainability and profitability of your business.

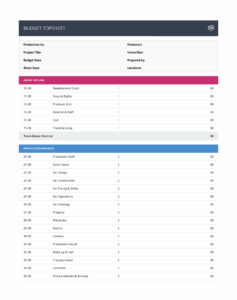

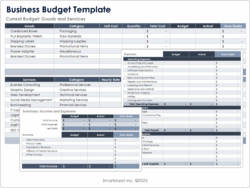

But let’s be honest, creating a comprehensive budget from scratch can feel like a monumental task. That’s why having a specialized budget template for manufacturing company operations can be an absolute game-changer. It provides a structured framework, ensuring you don’t miss any critical financial elements specific to your industry.

Understanding The Core Components Of A Manufacturing Budget

So, what exactly goes into a budget tailored for the manufacturing sector? It’s far more intricate than a simple profit and loss statement. We’re talking about a detailed breakdown that covers everything from the factory floor to the shipping dock, ensuring every operational cost and revenue stream is accounted for. Think of it as mapping out the financial lifeblood of your entire production process.

A great template guides you through these complexities, helping you categorize and track spending effectively. It moves beyond generic accounting, delving into the nuances of direct and indirect costs that are unique to manufacturing. This level of detail is crucial for making informed decisions about production levels, pricing strategies, and even capital investments.

Let’s delve into some of the fundamental elements that every effective manufacturing budget should include. Understanding these will not only help you fill out your template but also provide deeper insights into your company’s financial health and operational efficiency.

One of the first things you’ll want to clearly outline is your revenue. This isn’t just about total sales; it needs to consider different product lines, expected sales volumes, and any seasonal fluctuations that might impact your cash flow. Accurate revenue projection sets the stage for all subsequent budgeting decisions.

Following revenue, the expenditure side gets really detailed. It encompasses all the costs associated with transforming raw materials into finished goods. This is where the true manufacturing specificities come into play, differentiating it from service-based businesses.

Direct Costs

These are expenses directly tied to the production of your goods. They fluctuate with your production volume and are usually easier to track per unit.

- Raw Materials: The cost of all components that go into your product. This needs careful forecasting, considering supplier prices, bulk discounts, and potential supply chain disruptions.

- Direct Labor: Wages paid to employees directly involved in the manufacturing process, such as assembly line workers or machine operators. This can include base pay, overtime, and associated benefits.

Indirect Costs (Manufacturing Overhead)

These are costs associated with the manufacturing process but not directly traceable to a specific product unit. They are essential for keeping the factory running.

- Indirect Materials: Supplies used in the factory but not part of the finished product, like lubricants for machinery, cleaning supplies, or small tools.

- Indirect Labor: Wages for factory supervisors, maintenance staff, quality control personnel, and other support roles that are not directly producing goods but are vital for operations.

- Factory Utilities: Electricity, water, and gas used in the manufacturing facility.

- Rent or Property Taxes: Costs associated with the factory building itself.

- Depreciation of Machinery: The gradual loss of value of your production equipment over time.

- Maintenance and Repairs: Costs to keep your machinery and facility in good working order.

Operating Expenses (Non-Manufacturing)

These are the costs to run the business outside of direct production, such as:

- Selling Expenses: Marketing, advertising, sales commissions, and shipping costs to get products to customers.

- Administrative Expenses: Office salaries, legal fees, accounting, office supplies, and general overhead.

Capital Expenditure (CapEx)

This section is for significant investments in assets that will benefit the company for more than one year.

- New Machinery and Equipment: Purchases of production lines, robots, or significant upgrades.

- Building Improvements: Major renovations or expansions of the manufacturing facility.

Customizing Your Budget Template For Optimal Results

Finding a generic budget template for manufacturing company operations is a great starting point, but the real power comes from tailoring it to your unique business model. Every manufacturing company has its own intricacies, from specialized production processes to unique supply chains and distribution channels. A one-size-fits-all approach simply won’t cut it if you want truly actionable financial insights.

Think about your specific industry. Are you in food processing, automotive parts, textiles, or electronics? Each sector has distinct cost drivers, regulatory requirements, and revenue streams. Your template should reflect these specificities, allowing you to track the metrics that matter most to your decision-making. Don’t be afraid to add custom categories or tweak existing ones to better represent your operations.

Beyond industry specifics, consider your company’s size and growth stage. A startup might need a simpler budget focusing on cash flow and initial capital, while a large, established enterprise will require more complex departmental budgets and long-term forecasting. The goal is to make the template a living document that evolves with your business, not a rigid set of boxes to passively fill. Regularly review and update it to ensure it remains relevant and effective.

Here are some tips for making your budget template truly your own:

- Start with a Baseline: Use historical data from previous years to establish realistic projections for your current budget.

- Forecast Sales Accurately: Collaborate with your sales and marketing teams to create realistic revenue targets, considering market trends, product launches, and economic outlooks.

- Engage Department Heads: Solicit input from production managers, procurement, and other department leads. They have valuable insights into their operational costs and needs.

- Build in Contingencies: Always allocate a buffer for unexpected expenses or revenue shortfalls. Manufacturing can be unpredictable, with machinery breakdowns or sudden material price increases.

- Regular Review and Adjustment: Your budget shouldn’t be set in stone. Review it monthly or quarterly against actual performance and make necessary adjustments to stay on track.

- Integrate with Other Systems: If possible, link your budget template to your accounting software or ERP system for easier data entry and reconciliation.

Implementing a robust budget and utilizing a tailored template is more than just good financial practice; it’s a strategic imperative for any manufacturing company aiming for sustained success. It transforms complex financial data into clear, actionable insights, empowering you to make informed decisions that drive efficiency, manage costs, and fuel growth. By taking the time to understand your financial landscape through a well-structured budget, you gain unparalleled control over your operational destiny.

Embrace the budgeting process not as a chore, but as an essential tool for navigating the competitive manufacturing world. With a carefully crafted and consistently updated budget, your company will be better equipped to adapt to market changes, seize new opportunities, and build a resilient foundation for future prosperity.