Heavy equipment is the backbone of many industries, from construction and agriculture to mining and logistics. These powerful machines represent a significant investment, and their continuous, reliable operation is crucial for project timelines and overall business profitability. Just like any high-performing asset, heavy equipment requires consistent care and attention to truly thrive.

Neglecting maintenance can lead to unexpected breakdowns, costly repairs, and significant downtime, which can ripple through an entire operation. That’s where a systematic approach to maintenance becomes not just a good idea, but an absolute necessity. Keeping track of every service, inspection, and repair ensures your machines are always ready for the demands of the job.

Why a Dedicated Heavy Equipment Maintenance Log Template is Essential

Imagine trying to keep track of every oil change, tire rotation, hydraulic fluid check, and component replacement across an entire fleet of excavators, dozers, and loaders, all without a central system. It sounds like a recipe for chaos, doesn’t it? That’s precisely why having a robust heavy equipment maintenance log template isn’t just a convenience; it’s a strategic business tool. It moves you from reactive fire-fighting to proactive planning, saving you headaches and money in the long run.

One of the most immediate benefits you’ll see is in cost control. Preventive maintenance, meticulously tracked through a log, almost always costs less than emergency repairs. By identifying small issues before they escalate, you avoid catastrophic failures that can sideline a machine for weeks and rack up astronomical repair bills. Think about the labor costs for urgent repairs versus scheduled service, or the price difference between replacing a worn part and replacing an entire damaged assembly.

Beyond the financial implications, safety is paramount. Properly maintained equipment is safer equipment. Regular checks logged in a template help ensure that critical safety components like brakes, lights, and emergency shut-offs are always in working order, protecting your operators and anyone working around the machinery. It also fosters a culture of responsibility and attention to detail among your team.

Furthermore, a detailed log provides invaluable historical data. This information is crucial for making informed decisions about equipment lifespan, when to schedule replacements, and even for negotiating better resale values. When you can show a prospective buyer a complete service history documented through a heavy equipment maintenance log template, it adds significant value and credibility to your asset.

Key Benefits of Using a Structured Template

- Improved operational efficiency by minimizing unexpected breakdowns

- Reduced downtime, keeping projects on schedule and budgets intact

- Extended equipment lifespan, maximizing your initial investment

- Enhanced safety for operators and on-site personnel

- Better budget planning and forecasting for maintenance expenses

- Easier compliance with industry regulations and insurance requirements

- Optimized resale value through comprehensive service records

Ultimately, a well-implemented template streamlines your maintenance operations, ensuring consistency across all pieces of equipment and all personnel. It creates a standardized procedure that leaves no room for guesswork or missed steps, no matter who is performing the service or when. It also makes auditing and performance reviews much simpler, giving you a clear picture of your fleet’s health at any given moment.

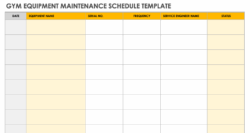

What to Include in Your Heavy Equipment Maintenance Log Template

Creating an effective heavy equipment maintenance log template means knowing exactly what information you need to track. It’s about striking a balance between comprehensive detail and usability, ensuring that every entry provides meaningful data without becoming overly cumbersome. The goal is to build a clear, chronological record that tells the complete story of your equipment’s maintenance journey.

First and foremost, your template needs to clearly identify the equipment in question. This might seem obvious, but with multiple machines that are similar, accurate identification is key to avoiding mix-ups and ensuring the right records are attributed to the right asset.

Here are some essential identification details:

- Equipment ID or Asset Number

- Make and Model of the machine

- Serial Number

- Date of Purchase or Lease Start Date

- Current Odometer Reading or Hour Meter Reading (at the time of service)

- Primary Location or Project Site where the equipment is typically deployed

Next, you’ll want to capture all the specifics of each maintenance event. This is where the bulk of your data will live, detailing what was done, by whom, and when. The more precise you are here, the more valuable your log becomes for future planning and troubleshooting.

Key details for each service entry include:

- Date of Service

- Type of Service Performed (e.g., routine inspection, oil change, hydraulic system check, tire rotation, brake service, engine overhaul)

- Performed By (Name or ID of the technician/mechanic)

- Parts Used (including part numbers if available, and quantity)

- Cost of Service (labor and parts)

- Next Scheduled Service Date or Next Hour Meter Reading for Service

- Detailed Notes or Observations (any issues found, recommendations, or special instructions)

It’s also beneficial to track consumables and wear parts like filters, belts, and hoses. Understanding their replacement cycles can help you anticipate needs and stock necessary inventory, preventing delays when a part is needed immediately. Over time, this data allows you to identify trends, such as which components wear out fastest on specific models or under certain operating conditions. This predictive insight can save substantial resources.

By diligently filling out each section of your heavy equipment maintenance log template, you’re not just recording history; you’re building a powerful dataset that can inform your purchasing decisions, refine your maintenance schedules, and ultimately contribute to the longevity and profitability of your entire fleet. It empowers you to move beyond reactive repairs to a more strategic, data-driven approach to asset management.

Keeping diligent records of your heavy equipment’s service history is more than just good practice; it’s a fundamental pillar of sound asset management. These detailed logs provide unparalleled insights into your machinery’s performance, helping you make informed decisions that safeguard your investments and enhance operational safety. It’s about building a legacy of care that translates directly into reliability and efficiency on the job site.

Embracing a structured approach to tracking maintenance ensures that every piece of equipment operates at its peak, minimizes unexpected costs, and keeps your projects moving forward without unnecessary interruptions. By prioritizing meticulous record-keeping, you’re not just maintaining machines; you’re cultivating a robust, resilient operation ready for any challenge.