Maintaining a pristine golf course is a significant undertaking, one that relies heavily on a fleet of specialized equipment. From the greens mowers meticulously cutting each blade of grass to the utility vehicles transporting supplies, every piece plays a crucial role in delivering the exceptional experience golfers expect. When this machinery isn’t running optimally, it doesn’t just slow things down; it can impact the very quality of your fairways and greens, directly affecting member satisfaction and your course’s reputation.

This is where a systematic approach to equipment care becomes indispensable. Imagine the frustration of an unexpected breakdown right before a major tournament, or the escalating costs from neglected routine service. Having a clear, consistent method for tracking all maintenance activities isn’t just good practice; it’s essential for operational longevity and financial prudence. This guide will walk you through the importance and practicalities of a robust golf course equipment maintenance log template, helping you keep your valuable assets in top shape.

Why a Robust Equipment Maintenance Log is Non-Negotiable for Golf Courses

Running a golf course efficiently means having a clear understanding of your equipment’s health at all times. Think of your maintenance log as the detailed health record for every mower, tractor, and sprayer on your property. Without it, you’re essentially flying blind, reacting to problems as they occur rather than proactively preventing them. This reactive approach inevitably leads to more downtime, higher repair costs, and a constant scramble to keep operations smooth.

A well-maintained log helps you extend the lifespan of your expensive machinery. Just like a car needs regular oil changes and tire rotations, golf course equipment thrives on scheduled preventive maintenance. Documenting these services ensures that no vital task is overlooked, preventing minor issues from escalating into major, costly repairs. It also creates a historical record, allowing your team to identify patterns, such as a particular machine consistently needing a specific part, which can inform future purchasing decisions or technician training.

Operational efficiency also sees a huge boost. When every piece of equipment has a clear service history, troubleshooting becomes much simpler. Technicians can quickly review past repairs or routine checks, speeding up diagnosis and getting machines back into service faster. This minimizes unexpected interruptions to your daily course upkeep schedule, ensuring your team can focus on their primary tasks without constant equipment headaches.

Beyond the immediate operational benefits, a comprehensive maintenance log also plays a critical role in safety and compliance. Regular inspections and servicing logged in your system help ensure that all safety features are operational and that the equipment meets industry standards. This not only protects your staff from potential hazards but also helps your course comply with regulatory requirements, reducing the risk of fines or legal issues.

Finally, effective logging directly impacts your bottom line. By preventing major breakdowns and extending equipment life, you reduce capital expenditure on new machines and control repair costs. It allows for better budgeting by forecasting future maintenance needs and parts requirements more accurately. The insights gained from a detailed golf course equipment maintenance log template are invaluable for long-term strategic planning and resource allocation.

Key Benefits You’ll Experience

- Extended Equipment Lifespan: Regular, documented maintenance prevents premature wear and tear.

- Enhanced Safety: Ensures all machinery is operating safely for your staff and visitors.

- Reduced Operational Costs: Minimize expensive emergency repairs and optimize fuel efficiency.

- Improved Budgeting: Predict future maintenance expenses with greater accuracy.

- Better Regulatory Compliance: Maintain records for inspections and safety audits.

Common Equipment Requiring Diligent Tracking

Almost every powered piece of equipment on your course should have its own entry in your maintenance log. Prioritizing consistent tracking for these assets is crucial for smooth operations:

- Greens Mowers (Walk-behind and Riding)

- Fairway Mowers

- Rough Mowers

- Tractors (with various attachments)

- Utility Vehicles (Golf Carts, UTVs)

- Sprayers and Spreaders

- Aerators and Verticutters

- Generators and Pumps

Crafting Your Ideal Golf Course Equipment Maintenance Log Template

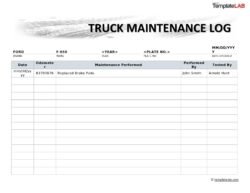

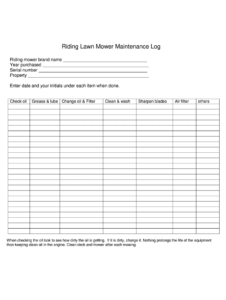

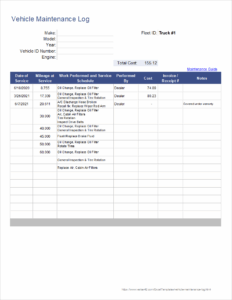

Creating an effective golf course equipment maintenance log template doesn’t have to be complicated, but it does need to be thorough and user-friendly. The goal is to capture all essential information in a standardized format, making it easy for anyone on your team to understand a machine’s history at a glance. Whether you opt for a digital spreadsheet, specialized software, or a binder of printed forms, consistency is absolutely key to its success.

Start by identifying the critical data points you need for each piece of equipment. Think about what information would be most valuable when diagnosing a problem, scheduling future service, or evaluating a machine’s performance over time. A good template acts as a central repository for this data, preventing information from being lost or forgotten amidst the hustle and bustle of daily course operations.

Your template should differentiate between various types of maintenance: routine preventive service, scheduled major overhauls, and unexpected repairs. This distinction helps in analyzing trends and optimizing your maintenance schedule. For instance, if a specific mower consistently requires unscheduled repairs between its routine service intervals, it might indicate a deeper issue, a need for more frequent preventive checks, or even that the machine is nearing the end of its reliable service life.

Beyond merely logging the work done, ensure your template encourages adding notes and observations. Sometimes, a technician might notice a minor issue that doesn’t warrant immediate repair but could become a problem later. Documenting these observations can be incredibly useful for future service calls. It transforms the log from a simple checklist into a valuable tool for proactive management and informed decision-making.

Essential Fields for Your Maintenance Log

- Equipment ID/Serial Number: Unique identifier for each machine.

- Date of Service: When the maintenance was performed.

- Type of Service: (e.g., Oil Change, Blade Sharpening, Tire Rotation, Engine Repair, Inspection).

- Hours/Mileage at Service: The machine’s usage meter reading.

- Parts Used: List all replacement parts with part numbers if available.

- Cost of Parts and Labor: Financial tracking for budgeting.

- Technician Name: Who performed the work.

- Next Scheduled Service: Date or usage meter reading for the next planned maintenance.

- Notes/Observations: Any specific comments, issues found, or recommendations.

Implementing a robust system for tracking your golf course equipment maintenance is an investment that pays dividends in longevity, efficiency, and ultimately, the superb condition of your course. By adopting a well-structured log, you’re not just recording data; you’re building a foundation for proactive management that minimizes downtime, controls costs, and ensures your machinery consistently performs at its peak. This systematic approach contributes significantly to the overall success and reputation of your golf course, allowing your team to focus on what they do best: creating an unforgettable golfing experience.