Utilizing a predefined structure for managing production adjustments facilitates improved communication, minimizes errors stemming from miscommunication, and provides a verifiable audit trail. This can lead to increased efficiency in implementing changes, reduced production downtime, and enhanced overall product quality.

This foundation of controlled change management allows exploration of key areas such as the core components of a typical form, best practices for completion and implementation, and the integration with broader quality management systems. Understanding these aspects is crucial for maximizing the effectiveness of any change management process.

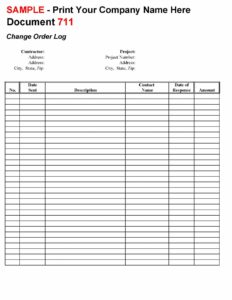

Key Components of a Change Control Document

Effective change management relies on a well-structured document outlining all necessary information. Several key components contribute to a comprehensive and actionable form.

1. Change Request Identifier: A unique number assigned to each request allows for easy tracking and referencing throughout the change lifecycle.

2. Requestor Information: Identifying the individual or department initiating the change ensures clear points of contact and accountability.

3. Date of Request: Recording the submission date provides a chronological record for auditing and reporting purposes.

4. Description of Change: A detailed explanation of the proposed modification, including the rationale and intended outcome, ensures clarity and shared understanding.

5. Affected Products/Processes: Clearly listing all impacted items allows for accurate assessment of the change’s scope and potential consequences.

6. Justification for Change: Providing the reasoning behind the proposed modification helps stakeholders evaluate its necessity and potential benefits.

7. Implementation Plan: Outlining the steps required to implement the change, including timelines and resource allocation, promotes organized execution.

8. Approval Signatures: Designated individuals authorized to approve the change provide documented consent and accountability.

These elements provide a robust framework for managing proposed modifications, ensuring traceability and minimizing the risk of errors during implementation. A well-defined structure enables effective communication and collaboration among stakeholders, contributing to smoother transitions and improved outcomes.

How to Create a Manufacturing Change Request Template

Developing a standardized template for managing change requests ensures consistency and efficiency in handling production modifications. A well-structured template facilitates clear communication and reduces the likelihood of errors during implementation.

1. Define Scope and Objectives: Clearly outline the purpose of the template and the types of changes it will encompass. Consider the specific needs of the manufacturing environment and the level of detail required for each change request.

2. Identify Key Information Fields: Determine the essential data points needed to document a change request thoroughly. This typically includes a unique identifier, requestor information, date, description of the change, affected products/processes, justification, implementation plan, and approval signatures.

3. Choose a Format: Select a format that aligns with existing documentation practices and software systems. Options include digital forms, spreadsheets, or dedicated change management software. Ensure the chosen format supports version control and access control.

4. Develop Clear Instructions: Provide clear and concise instructions for completing each section of the template. This minimizes ambiguity and ensures consistent data entry.

5. Establish a Review and Approval Process: Define the workflow for reviewing and approving change requests. Specify the roles and responsibilities of individuals involved in the approval process. Include clear criteria for evaluating the proposed changes.

6. Implement and Train: Introduce the new template to relevant personnel and provide training on its proper use. Ensure all stakeholders understand the importance of adhering to the established process.

7. Regularly Review and Update: Periodically review the template’s effectiveness and make necessary updates based on user feedback and evolving business needs. This ensures the template remains relevant and continues to support efficient change management.

A well-designed template, coupled with clear procedures and adequate training, provides a robust framework for managing manufacturing changes effectively. This proactive approach minimizes disruption, improves product quality, and enhances overall operational efficiency.

Standardized documentation for proposed modifications provides a structured approach to managing change within manufacturing environments. Key benefits include improved communication, reduced errors, increased efficiency, and enhanced product quality. Essential components of such documentation include a unique identifier, requestor information, a detailed change description, affected items, justification, an implementation plan, and approval signatures. Creating effective documentation involves defining scope, identifying key fields, selecting a suitable format, developing clear instructions, and establishing a review and approval process.

Effective change management is crucial for competitiveness and continuous improvement within the manufacturing industry. Adopting formalized processes for documenting and implementing change contributes significantly to operational efficiency, product quality, and overall business success. Regular review and adaptation of these processes ensure continued relevance and effectiveness in the face of evolving industry demands.