Utilizing such a form offers several advantages. Streamlined communication, reduced administrative overhead, and improved efficiency are key benefits. Standardized documentation also promotes thoroughness, ensuring all necessary information is captured, which contributes to a more accurate and reliable inspection process. Ultimately, this leads to better decision-making and risk mitigation.

This foundation of clear communication and structured information is crucial for understanding the broader topics of quality control, regulatory compliance, and operational efficiency, all of which will be explored further in this article.

Key Components of an Inspection Request Form

Effective inspection requests require specific information to ensure clarity and completeness. The following components are essential for a well-structured form:

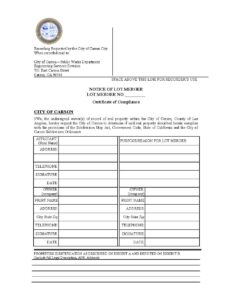

1: Identification of Requester: Clear identification of the individual or entity initiating the inspection request, including contact details, is crucial for efficient communication and follow-up.

2: Subject of Inspection: Precise identification of the item, location, or process requiring inspection is necessary to focus the inspection efforts effectively.

3: Purpose of Inspection: A concise statement outlining the reason for the inspection helps define the scope and objectives of the assessment.

4: Date and Time: Specifying preferred and/or acceptable dates and times for the inspection facilitates scheduling and coordination.

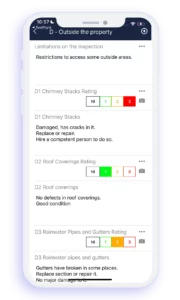

5: Specific Requirements: Detailed information about specific areas of focus, relevant regulations, or particular standards aids inspectors in conducting a thorough evaluation.

6: Supporting Documentation: Inclusion of relevant documents, such as plans, specifications, or previous inspection reports, provides valuable context for the inspection.

7: Authorization: Signatures or other forms of approval may be required to authorize the inspection and ensure proper procedures are followed.

A comprehensive form containing these elements facilitates a well-defined, efficient, and effective inspection process, contributing to better outcomes and informed decision-making.

How to Create a Request for Inspection Template

Developing a standardized inspection request form involves careful consideration of several key elements. A well-designed template ensures consistency, clarity, and efficiency throughout the inspection process.

1: Define the Scope: Determine the range of inspections the template will cover. This clarifies the types of requests the form will accommodate and ensures relevant information is captured.

2: Identify Essential Information: Specify the required information, such as requester details, subject of inspection, purpose, date/time preferences, and specific requirements. This establishes a baseline for all inspection requests.

3: Design the Layout: Create a clear and organized layout for the form. Logical grouping of information and clear labeling enhance readability and ease of use.

4: Incorporate Instructions: Provide concise instructions for completing the form. Clear guidance minimizes errors and ensures accurate information is provided.

5: Establish a Review Process: Implement a review and approval process for completed forms. This step ensures accuracy and completeness before the inspection is scheduled.

6: Utilize Technology: Consider using digital tools or software to create and manage inspection requests. This can automate workflows, improve efficiency, and facilitate data analysis.

7: Implement and Train: Distribute the template and provide training to all relevant personnel. This ensures consistent application and maximizes the effectiveness of the standardized form.

A well-structured, comprehensive template, combined with proper implementation and training, contributes significantly to a robust and efficient inspection process, ultimately leading to improved quality, compliance, and operational effectiveness.

Standardized forms for requesting inspections provide a crucial foundation for effective assessment and evaluation across diverse industries. From facilitating clear communication and streamlining workflows to ensuring thoroughness and promoting data-driven decision-making, these structured tools contribute significantly to quality control, regulatory compliance, and operational efficiency. The careful design, implementation, and utilization of these forms empower organizations to proactively manage risk and maintain high standards.

Effective implementation of standardized inspection request procedures represents a commitment to continuous improvement and proactive risk management. By embracing these practices, organizations can enhance operational effectiveness and contribute to a culture of quality and compliance. This proactive approach strengthens not only individual processes but also the overall organizational framework, paving the way for future growth and success.